THE START OF OUR JOURNEY

The weather has been kind to us

today as we leave our Elgin offices and head South to our

destination - Imperial Distillery, Carron. Cutting through the

landscape, driving through small communities, passing the Rothes

Glen Hotel with its Highland cattle in the fields we also pass a

number of distilleries. Benriach,  Glenlossie,

Longmorn, Glen Grant and Speyburn to name a few. As we pass

through the small village of Aberlour, home of Walkers

Shortbread, we drive up a steep road taking us nearer to Carron

where, in a hollow on the banks of the River Spey and next to the

former Carron station, Imperial Distillery lies.

Glenlossie,

Longmorn, Glen Grant and Speyburn to name a few. As we pass

through the small village of Aberlour, home of Walkers

Shortbread, we drive up a steep road taking us nearer to Carron

where, in a hollow on the banks of the River Spey and next to the

former Carron station, Imperial Distillery lies.

Built in 1897, by Thomas MacKenzie, it coincided with Queen Victoria's Diamond Jubilee which was no doubt an in fluencing factor when naming the distillery. With a shaky start and history Imperial distillery started production in the summer of 1898 only to close a year later for over 20 years. Production did recommence in 1919 but, again, for only six years. On our approach we are impressed by the location of such a commanding distillery. Pine forests surround every viewpoint, and there are many well kept distillery houses, a quaint traditional red telephone box and neatly cut lawns surround the distillery buildings, it makes for an impressive sight.

The construction of Imperial differs from other Speyside distilleries as it was built of red Aberdeen brick with an iron beam and pillar framework to make it fire resistant. A nearby water supply, of quality, is a key factor in the location of any suitable distillery site. Imperial, however is 60 feet above the River Spey next to a railway line. The water supply originates from the Mannoch hills to form the Ballintom Burn from where the water is drawn. Although, the location of the railway line was considered originally to be important than proximity to the Spey it did not stop the line from closing in the late 1960's.

COOLING WATER

A distillery requires a large quantity of cold water to supply the condensers in the still house. This water cools the hot alcohol vapours from the stills and leaves the condensers at a considerably higher temperature.

At Imperial Distillery the cooling water travels for two and a half miles and comes from the Ballintomb Burn. As it travels by gravity there is no power required to feed the water into the condensers, which makes for a very efficient system.

A problem arose with reintroducing the hot water from the condensers back into the burn as, by law, it was too hot. Allied's Chief Engineer Manager, Tom Dunn, managed to overcome this problem by designing a series of walls within the dam. This created a long canal by which the hot water has to travel before it reaches the outlet and is reintroduced into the burn - safely.

CHANGING HANDS

Imperial

was built; 1898 ownership transferred to Dailuaine-Talisker

Distilleries, 1899 Imperial closed; 1919 re-opened until 1925

when it also passed to new owners - DCL; 1955 Under new

management SMD, production recommenced after complete rebuild of

equipment, at the same time the gilt imperial crown was taken

down from the malting kiln due to rust; During the 1980's it was

silent yet again, 1989 Allied Distillers became the new operators

who, after some work, reopened the distillery in 1991.

Imperial

was built; 1898 ownership transferred to Dailuaine-Talisker

Distilleries, 1899 Imperial closed; 1919 re-opened until 1925

when it also passed to new owners - DCL; 1955 Under new

management SMD, production recommenced after complete rebuild of

equipment, at the same time the gilt imperial crown was taken

down from the malting kiln due to rust; During the 1980's it was

silent yet again, 1989 Allied Distillers became the new operators

who, after some work, reopened the distillery in 1991.

DISTILLERY MANAGER

Ronnie MacDonald is, today, the Distillery Manager at Imperial. He also manages Scapa, 118 miles away, and is involved in Tormore and Glentauchers distilleries as well. Ronnie has a long history with the distillery as his father was also distillery manager at Imperial during the 1950's and 60's. As young as six Ronnie became involved in the distillery. At the official reopening ceremony in 1955, Ronnie presented Mr s Grant from Carron House with a bouquet for opening the distillery. Ronnie has been the distillery manager for over four years and has been in the industry since 1969. With advancements in the operating technology it now only requires 9 distillery workers to operate a five day production schedule - all nine men work close together with skills and expertise being shared and passed on.

DISTILLERY STATISTICS

| Malting Capacity | Nil |

| Malt Source | Burghead Maltings |

| Malt Type | Predominately Chariot, lightly peated |

| Malt Storage | 10 Malt Bins, each holding 30 tonnes |

| Mill Type | Porteus |

| Grist Storage | 4 Hoppers, each holding 11.56 tonnes |

| Mush Tun Construction | Traditional, stainless steel with paddles |

| Mash Size | 11.56 tonnes |

| No. of Wash Backs | 6 |

| Wash Back Construction | Larch |

| Wash Back Capacity | 56,500 litres |

| Yeast | Brewers & Distillers |

| No of Wash Stills | 2 |

| Wash Still Charge | 18,800 litres |

| Heat Source | Heating pans |

| No. of Spirit Stills | 2 |

| Spirit Still Charge | 21,000 litres |

| Heat Source | Steam coils and pans |

| Current Annual Distillery Output | 1.6 million Litres of alcohol. |

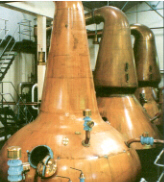

THE STILLS

There are two wash stills and two spirit stills which currently produce 1.6 million litres of alcohol a year. The wash stills have a shape known as 'lamp glass' - where the neck of the still is tucked in above the pot. The spirit stills are tradtional in shape. Both types stand, approximately, over 18 feet tall with the lyne arm on a slight decline into the condensers.

Read our tasting notes for Imperial Whisky.

Home | History | Sample Room | News | Product Range | Shop