THE START OF THE JOURNEY

Not far from our main offices in Elgin, Benromach distillery stands on the outskirts of the ancient town of Forres, in the beautiful 'Laich of Moray'. Approaching the distillery from Elgin the location is visable from the road to the right of the Forres bypass. The newly white washed building with it's red brick chimney, just under 100 feet tall, stands majestically above the renowned lush arable landscape of the Laich of Moray.

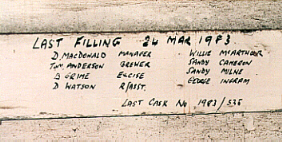

THE END OF AN ERA

The 24th March 1983 marked an historic occassion for many who worked at Benromach Distillery. It was to be the day of the very last filling at the distillery under the ownership of United Distillers. A day that was not to be passed without some historic mark. On clearing up the filling store we found that the workers on that day had witnessed the last filling and signed their names on the filling store wall

CHANGING HANDS

1898; BENROMACH distillery established by partners, Duncan McCallum of Glen Nevis distillery and F.W. Brickman a Spirit broker from Leith.

1907-1910; operated during these years by Duncan McCallum and revived after World War I by BENROMACH Distillery Ltd.

1931-1936; Silent,

1938; BENROMACH was acquired by Train & McIntyre subsidiary of Associated Scottish Distillers Ltd.

1953; Train & McIntyre was purchased by the DCL and BENROMACH transfered to SMD. Rebuilt 1966, 1974 two stills installed.

1983; closed.

1992; site was sold to Gordon & MacPhail.

1997 BENROMACH distillery starts to get an overhaul.

1998; two stills installed along with all production equipment.

October 15th 1998 BENROMACH officially re-opened by H.R.H The Prince of Wales Duke of Rothesay.

DISTILLERY TEAM

Bob Murray joined the Gordon & MacPhail team only recently

but has been a key player in the development of Benromach

Distillery. Bob, who previously managed a distillery in Speyside,

brings with him a wealth of knowledge having over 25 years experience in the distilling industry. He will meet

the challenge of ensuring that the production at Benromach will

reach our high quality control standards. Keith Cruickshank, was

recruited to assist Bob. Keith also comes from a distillery

background having experienced various roles in Speyside

distilleries.

experience in the distilling industry. He will meet

the challenge of ensuring that the production at Benromach will

reach our high quality control standards. Keith Cruickshank, was

recruited to assist Bob. Keith also comes from a distillery

background having experienced various roles in Speyside

distilleries.

"The opportunity to be part of a project of this type, at the early stages, does not happen often in anyone's lifetime. For Keith and myself this has been a personal challenge which we have both enjoyed and can only see the enjoyment and challenges continuing."

BOB MURRAY.

CONSTRUCTING THE WASHBACKS

Constructing the washbacks properly, whilst looking easy, is in fact like a Krypton Factor puzzle. Each length of larch is made to fit snuggly into each other. As wood has its own characteristics this can sometimes prove difficult. Once arranged in order they are then fixed onto the solid bottom and fixed together by 'dowels'. As they are set in position the staves are finally fixed in by a number of different sized steel hoops. The wood is then kept moist ensuring that it does not dry out and shrink - which will certainly cause leaks.

DISTILLERY STATISTICS

| Malt Source | Moray Firth Maltings and other maltsters |

| Malt Type | Predominately Chariot, lightly peated |

| Malt Storage | 1 Malt Bin, holding 30 tonnes |

| Mill Type | Boby - 4 roller |

| Grist Storage | 1 Hopper, holding 2 tonnes |

| Mush Tun Construction | Stainless steel - semi-lauter |

| Mash Size | 1.5 tonnes |

| No. of Wash Backs | 4 |

| Wash Back Construction | Larch |

| Wash Back Capacity | 11,000 litres |

| Yeast | Brewers & Distillers |

| No of Wash Stills | 1 |

| Wash Still Charge | 7,500 litres |

| Heat Source | Steam heating plates |

| No. of Spirit Stills | 1 |

| Spirit Still Charge | 5,000 litres |

| Heat Source | Steam heating plates |

| Current Annual Distillery Output | 500,000 - 750,000 Litres of alcohol. |

BENROMACH STILLS

Built in 1898, Benromach Distillery is believed to be the first distillery to install direct oil-firing under the stills. Back then Benromach was descibed as a striking distillery. Since 1983 Benromach Distillery has lain silent. Now in 1998 Gordon & MacPhail have re-equiped the distillery and distillation has once again started in this, Benromach's Centenary year.

The shape of the still is very

important in the final product. Often when stills have to be

replaced they are copied exactly - including bumps or dents. Tall

necked stills, tend to produce a finer, lighter spirit due to the

vapours condensing before reaching the swan neck and falling back

into the distillate to be redistilled. Shorter stills will

produce a fuller, richer spirit.

The shape of the still is very

important in the final product. Often when stills have to be

replaced they are copied exactly - including bumps or dents. Tall

necked stills, tend to produce a finer, lighter spirit due to the

vapours condensing before reaching the swan neck and falling back

into the distillate to be redistilled. Shorter stills will

produce a fuller, richer spirit.

At Benromach distillery the stills have been specifically designed to produce a full, rich spirit and are therefore shorter than some. With one wash still and one spirit still the production emphasis at Benromach is towards delivering the same high quality spirit, produced during it's first 100 years. The new stills are again heated by steam generated by an oil fired boiler.

Read our tasting notes for Benromach Whisky.

Home | History | Sample Room | News | Product Range | Shop