If you drive to Campbeltown, it always takes longer than you expect. This is an immutable fact of life, like DNA or the tide tables. But if you're hunting down whisky, the tortuously beautiful route down to the end of the Kintyre peninsula is worth every twist and turn.

While each malt distillery is different, surely none is more different than Springbank. A tourist magazine would probably gush that the past has stood still here: but it hasn't. It's just that the experience of the past has not been discarded, while any so-called advances of the present and future are never adopted for simple reasons of economy and efficiency. The whisky comes first.

And the result is a whisky-and a distillery-unique for several reasons. For Springbank does not make whisky the easy way (in fact it makes two of only three surviving Campbeltown malts, Springbank and Longrow: the third, a rarity, is Glen Scotia). Once there were nearly 30 Campbeltowns, a reason why this particular style of whisky still has its own separate classification. But it is no coincidence that the Springbank is still revered as a great classic.

So let's ask how they do it. First you

find that the distillery, approached down a battered lane between

a depot selling concrete slabs and an evangelical church, is not

a beauty designed for sightseer-orgasm. It's a working place

where whisky has been distilled (legally) since 1828 and

(illegally) from much earlier. Travelling abroad, to Italy or the

Greek islands, you might appreciate best the places which haven't

transformed themselves into fanciful tourist venues. Campbeltown

itself, and the Springbank Distillery, have this quality of

integrity.

So let's ask how they do it. First you

find that the distillery, approached down a battered lane between

a depot selling concrete slabs and an evangelical church, is not

a beauty designed for sightseer-orgasm. It's a working place

where whisky has been distilled (legally) since 1828 and

(illegally) from much earlier. Travelling abroad, to Italy or the

Greek islands, you might appreciate best the places which haven't

transformed themselves into fanciful tourist venues. Campbeltown

itself, and the Springbank Distillery, have this quality of

integrity.

So to the whisky-making. Springbank is the only remaining Scotch malt distillery which conducts the entire process itself on a single site. It starts with barley, and it ends up with bottled whisky. Unusually, it germinates all of the barley it uses in floor maltings and dries it in its own kiln. The huge majority of malt distillers now buy their raw material ready-prepared from industrial maltings. But Springbank's is the traditional way, the labour-intensive way, the way you might have thought had disappeared: and it gives the distillery absolute control over the quality of its whisky from start to finish.

Several things have made this possible. One is that the business has remained in the hands of the same family since pre-legal days. Another is that it doesn't keep the stills hammering away, day and night, in pursuit of some productivity record. It buys as much barley as it believes market conditions indicate, malts it and kilns it-and only then, when the bins are stocked with up to 200 tonnes of malted barley, does it start distilling. So in the average year, the stills will be operating for a total of only four months.

This is viable because the men who steep

the barley, germinate it on the malting floors and dry it in the

kiln, then change jobs to operate the mash tun, the washbacks and

the stills. At the same time Springbank's tiny bottling plant-fed

with matured whisky from its own warehouses-works all year round.

and something like 99 per cent of Springbank is bottles as a

single-malt, which is also very unusual.

This is viable because the men who steep

the barley, germinate it on the malting floors and dry it in the

kiln, then change jobs to operate the mash tun, the washbacks and

the stills. At the same time Springbank's tiny bottling plant-fed

with matured whisky from its own warehouses-works all year round.

and something like 99 per cent of Springbank is bottles as a

single-malt, which is also very unusual.

Director John McDougall, who has worked in distilling for 30 years and says he's "one of a dying breed" (although he looks extremely healthy), told me that computer-managed microchip whisky was an alien culture to Springbank. His whisky was made by real people. In fact, Springbank has a permanent workforce of 24, more than double that of an obsessively modernised distillery.

But brewer Hector Gatt showed me how even on the traditional malting floors reintroduced two years ago, the advantages of electricity are not ignored. The sprouting barley is turned by a machine resembling a lawnmower. But when this breaks down, which is not impossible, the men sigh, reach for the old wooden shovels which stand by in readiness against the wall, and laboriously turn the grain in the old way, by muscle-power.

There are changes also at the kiln, but nothing that you'd notice. The peat used for drying (more for Longrow, less to make Springbank) is now brought in from Islay. Once the distillery had its own local peat-banks, operated by two employees who would vanish up to the moor in April to cut and stack the aromatic fuel, and would rarely be seen again until October. Longrow, the more heavily-peated of these two malts, is quite a rarity and isn't made every year.

There's a row of three stills at

Springbank, but this doesn't mean that the whisky is

triple-distilled. Oh no. Nothing is that simple here. Hector Gatt

told me that in precise terms, it was distilled

"two-and-a-half times". Because this sounds impossible,

it requires some explanation.

There's a row of three stills at

Springbank, but this doesn't mean that the whisky is

triple-distilled. Oh no. Nothing is that simple here. Hector Gatt

told me that in precise terms, it was distilled

"two-and-a-half times". Because this sounds impossible,

it requires some explanation.

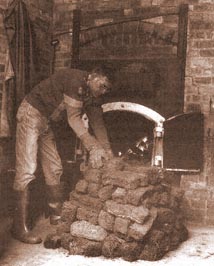

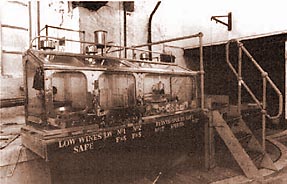

From any of the six larch-wood washbacks, the liquid goes first to the wash-still. Unusually (again) this is heated by a live flame from beneath, which requires a "rummager"-a sort of copper chain-mail mat-to circulate inside and prevent burning. From here, the low wines are treated again in the two spirit stills.

But one of the great characteristics of Springbank is its "body"-what some tasters would call its chewy quality. If the whisky was too strong in alcohol it would also be too light. So the stillman will add a small quantity of low wines from the first distillation to the liquid which is to go through the third still. How much to add is a matter of experience and fine judgement. You couldn't program this into a computer.

Then it goes for the long sleep. Springbank is bottled at 12, 15, 21, 25, and 30 years old. (Longrow, which is double-distilled, is usually bottled at 19 years.) So maybe, when you try Springbank, the great Campbeltown survivor, you now understand why it's...rather different.

Unless otherwise noted, all information in this site © The Scotch Malt Whisky Society, Edinburgh, Scotland, 1997.