Knockando

From Ledgers toComputers

Anthony Troon finds traditional standards liveon in the Speyside distillery that keeps a wardrobe of fortykilts.

I was looking over the old ledgers in the manager's office atKnockando-Glenlivet. There, in spidery handwriting from 30 May1898, were the figures that showed how it all began. Bushels ofmalt - 224; Gallons of wash - 4484; Remaining in store - nil;Depending feints - nil. The fact that there were no feintsbrought forward from a previous distillation told its own story.This was the record of the first malt whisky ever produced in adistillery which now has a worldwide reputation.

The Knockando ledgers, leather bound and weighty with a solemnfeeling of old-fashioned Scottish probity, are an amazingsurvival. They were found in an outhouse which was about to bedemolished, and their detailed, telltale figures reflect all theoptimism and anxiety of starting up a new malt whisky distilleryfrom scratch.

As I turned the weighty sheets,Knockando's manager, Innes Shaw, took a phone call and movedacross to his computer. He logged on and there was an exchange ofinstructions on a radio telephone. The computer started to churnout reams of statistics. We had reached the end of anothercentury, but it occurred to me that through the astonishingchanges in technology, from pen and inkwell to microchip, we weresaying basically the same things about the same glorious product.

As I turned the weighty sheets,Knockando's manager, Innes Shaw, took a phone call and movedacross to his computer. He logged on and there was an exchange ofinstructions on a radio telephone. The computer started to churnout reams of statistics. We had reached the end of anothercentury, but it occurred to me that through the astonishingchanges in technology, from pen and inkwell to microchip, we weresaying basically the same things about the same glorious product.

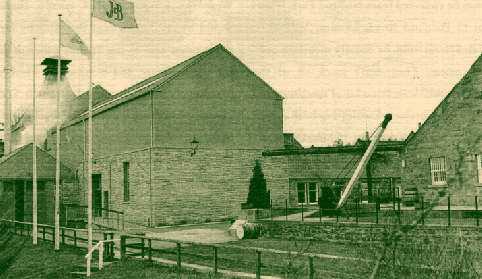

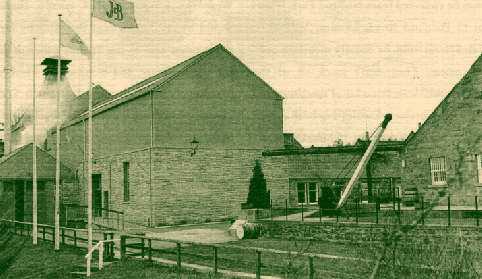

The village of Knockando is remote, beautifully remote. Yet asyou drive through the tiny settlement you are in a place of greatinfluence, for the three malts distilled nearby reach out asconstituents of major-selling blends on the world stage. Most ofthe Knockando goes into J&B Rare which has the second-biggestworldwide sales: the Cardhu goes into top-selling Johnnie Walker:and the Tamdhu is an essential part of The Famous Grouse.

Such commercial clout was undreamed ofwhen the first entry was made in the first Knockando ledger onbehalf of J Thompson Esq, spirit broker, Elgin, who built thissplendid little distillery. In fact, he was not to enjoy thefruits of it for long. In a hard time for the industry, thedistillery ceased production two years later and was bought in1904 by W & A Gilbey's for the bargain sum of £3,500.

Such commercial clout was undreamed ofwhen the first entry was made in the first Knockando ledger onbehalf of J Thompson Esq, spirit broker, Elgin, who built thissplendid little distillery. In fact, he was not to enjoy thefruits of it for long. In a hard time for the industry, thedistillery ceased production two years later and was bought in1904 by W & A Gilbey's for the bargain sum of £3,500.

When you turn off the road into the distillery grounds, youseem to have entered a separate village. There's a row of trimcottages built for the workers and (originally) for the residentexcisemen, overlooked in hierarchical splendour by slightlybigger management houses.

A newspaper account on the opening of the distillery in 1898provides a remarkable link with the present. One of the twocarpentry contractors is listed as 'Innes, Knockando' - thematernal great-grandfather of the present distillery manager.This great-grandfather had three sons, one who took over hisjoinery business, one who became manager at Cragganmore, and onewho became an exciseman... a clear indication of the importanceof whisky to the social and economic life of Speyside.

Now, the Knockando Distillery is part of InternationalDistillers & Vintners (owned by Grand Metropolitan Hotels)and is managed by Justerini & Brooks. The genial manager,Innes Shaw, didn't go directly into the business but firststudied electrical and electronic engineering at Aberdeen.'Engineering is a great discipline for problem-solving,' he saiddrily.

But you'd be hard-put to see evidence ofany problems at Knockando as it quietly and efficiently deliversits annual million litres AV for the good of mankind. Unlike mostmalt distilleries whose parent companies are involved inblending, Knockando no longer 'swaps' its product for others,devoting it entirely to J&B Rare and its own single maltbottlings. Therefore its availability to Society members is arare treat.

But you'd be hard-put to see evidence ofany problems at Knockando as it quietly and efficiently deliversits annual million litres AV for the good of mankind. Unlike mostmalt distilleries whose parent companies are involved inblending, Knockando no longer 'swaps' its product for others,devoting it entirely to J&B Rare and its own single maltbottlings. Therefore its availability to Society members is arare treat.

When there's to be a bottling of the single malt, about 400casks are selected. The contents are put together and 'married'for around three months before going into the bottle. Unusually,the label states the year of distillation and the year ofbottling. This allows the distillers to vary the period ofmaturation, between say 12 and 14 years, and make a judgement onwhen the whisky is at its peak.

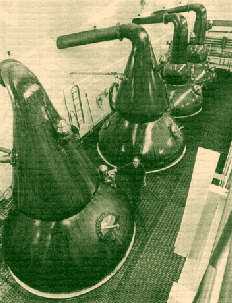

In 1969, the distillery increased output by partial rebuildingand adding a second pair of stills. It specifies that its malt,lightly-peated, must be of Scottish-grown barley, usually fromthe Black Isle or East Lothian. This is delivered in 25-tonneloads and stored in eight bins of 30 tonnes capacity.

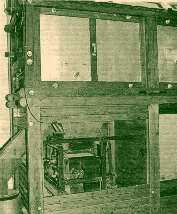

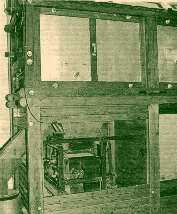

On its way to the mash tun, the gristfrom the four-roller Porteous mill is weighed by a clever yetsimple little device which has been doing the job faithfullysince 1921, supplied by W T Avery of Birmingham. It measures thegrist into 40 kilogram batches, so that 106 batches supply therequired 4.24 tonnes for mashing. From there, the worts progressto the wooden washbacks (wood being retained as a matter ofpolicy), entering at 19 degrees C and rising to 33 degrees on 46hours of fermentation.

On its way to the mash tun, the gristfrom the four-roller Porteous mill is weighed by a clever yetsimple little device which has been doing the job faithfullysince 1921, supplied by W T Avery of Birmingham. It measures thegrist into 40 kilogram batches, so that 106 batches supply therequired 4.24 tonnes for mashing. From there, the worts progressto the wooden washbacks (wood being retained as a matter ofpolicy), entering at 19 degrees C and rising to 33 degrees on 46hours of fermentation.

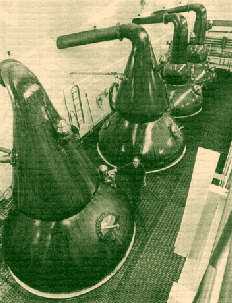

Then to the still room. The wash stills at Knockando areheated internally by three steam 'kettles' while the spiritstills have four. During the three-hour run of the middle cut,the spirit still temperature is reduced as much as possible tocollect only the higher order alcohols.

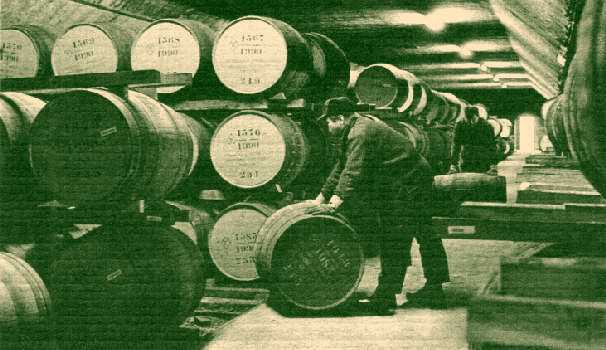

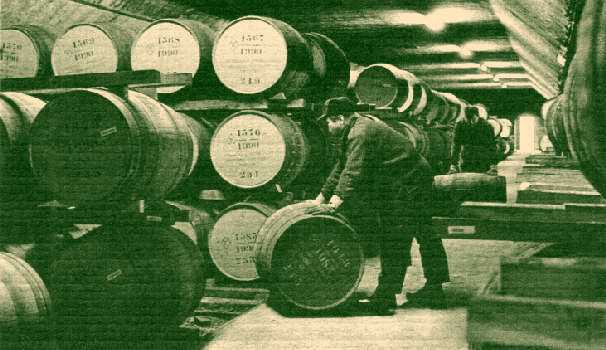

The 'No 3 Maturing Shed' again emphasises the adherence toTradition: an earthen floor covered with loose stones, with thehogsheads stacked only three-high and the larger butts two-high.Another former warehouse has been expensively converted into aspacious visitor centre: but Knockando-Glenlivet is not on thetourist 'whisky trail' and the guests who come here are from theinternational drinks trade. It's another indication ofKnockando's determination to conquer new markets whilesafeguarding the elegant style of the whisky.

It's here they keep a wardrobe of 40 kilts. The guests arepersuaded to take off their trousers and try them on. Theprospect of 40 Italian importers in the garb of the Gael mightnot have occurred to J Thompson Esq, spirit broker, Elgin. But hemight have wished he'd thought of it in time.

If you have comments about thissite, please contact the webmaster. Unless otherwise noted, all information in this siteİ The Scotch Malt Whisky Society, Edinburgh, Scotland, 1997.

As I turned the weighty sheets,Knockando's manager, Innes Shaw, took a phone call and movedacross to his computer. He logged on and there was an exchange ofinstructions on a radio telephone. The computer started to churnout reams of statistics. We had reached the end of anothercentury, but it occurred to me that through the astonishingchanges in technology, from pen and inkwell to microchip, we weresaying basically the same things about the same glorious product.

As I turned the weighty sheets,Knockando's manager, Innes Shaw, took a phone call and movedacross to his computer. He logged on and there was an exchange ofinstructions on a radio telephone. The computer started to churnout reams of statistics. We had reached the end of anothercentury, but it occurred to me that through the astonishingchanges in technology, from pen and inkwell to microchip, we weresaying basically the same things about the same glorious product. Such commercial clout was undreamed ofwhen the first entry was made in the first Knockando ledger onbehalf of J Thompson Esq, spirit broker, Elgin, who built thissplendid little distillery. In fact, he was not to enjoy thefruits of it for long. In a hard time for the industry, thedistillery ceased production two years later and was bought in1904 by W & A Gilbey's for the bargain sum of £3,500.

Such commercial clout was undreamed ofwhen the first entry was made in the first Knockando ledger onbehalf of J Thompson Esq, spirit broker, Elgin, who built thissplendid little distillery. In fact, he was not to enjoy thefruits of it for long. In a hard time for the industry, thedistillery ceased production two years later and was bought in1904 by W & A Gilbey's for the bargain sum of £3,500. But you'd be hard-put to see evidence ofany problems at Knockando as it quietly and efficiently deliversits annual million litres AV for the good of mankind. Unlike mostmalt distilleries whose parent companies are involved inblending, Knockando no longer 'swaps' its product for others,devoting it entirely to J&B Rare and its own single maltbottlings. Therefore its availability to Society members is arare treat.

But you'd be hard-put to see evidence ofany problems at Knockando as it quietly and efficiently deliversits annual million litres AV for the good of mankind. Unlike mostmalt distilleries whose parent companies are involved inblending, Knockando no longer 'swaps' its product for others,devoting it entirely to J&B Rare and its own single maltbottlings. Therefore its availability to Society members is arare treat. On its way to the mash tun, the gristfrom the four-roller Porteous mill is weighed by a clever yetsimple little device which has been doing the job faithfullysince 1921, supplied by W T Avery of Birmingham. It measures thegrist into 40 kilogram batches, so that 106 batches supply therequired 4.24 tonnes for mashing. From there, the worts progressto the wooden washbacks (wood being retained as a matter ofpolicy), entering at 19 degrees C and rising to 33 degrees on 46hours of fermentation.

On its way to the mash tun, the gristfrom the four-roller Porteous mill is weighed by a clever yetsimple little device which has been doing the job faithfullysince 1921, supplied by W T Avery of Birmingham. It measures thegrist into 40 kilogram batches, so that 106 batches supply therequired 4.24 tonnes for mashing. From there, the worts progressto the wooden washbacks (wood being retained as a matter ofpolicy), entering at 19 degrees C and rising to 33 degrees on 46hours of fermentation.