Strathmill

Our Hundredth Malt: AGreat Rarity from Banffshire

Few have tasted this secretive dram before itreaches the blenders. But Anthony Troon makes a house-call.

I went there to celebrate a centenary, and ended up with two.It was an irresistible coincidence: the one-hundredth distilleryto grace the bottling lists of the Scotch Malt Whisky Societyjust happened to have celebrated its one-hundredth anniversarylast year.

We are delighted to have made the century. There are fewerthan 100 malt distilleries presently working in Scotland, andonly 120 or so whiskies available in cask - if you count thenow-matured product of defunct distilleries.

It is significant also that ourhundredth whisky is so rare as a bottled single malt that it haseluded even the experts. In his Malt Whisky Companion, MichaelJackson lists it as one of six which appear never to have beenbottled as singles in recent times, even by independent bottlers.So mark well our tasting notes on No 100: you are unlikely to seethem elsewhere.

It is significant also that ourhundredth whisky is so rare as a bottled single malt that it haseluded even the experts. In his Malt Whisky Companion, MichaelJackson lists it as one of six which appear never to have beenbottled as singles in recent times, even by independent bottlers.So mark well our tasting notes on No 100: you are unlikely to seethem elsewhere.

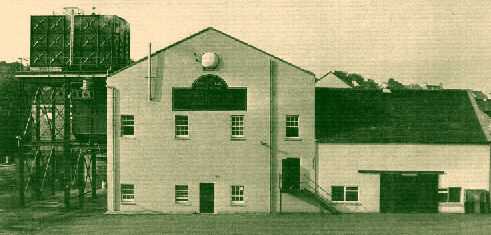

Characteristically, the Strathmill Distillery hides itselfshyly behind trees in a dip off the main road through theattractive town of Keith, Banffshire. Its boundaries are markedby the northerly River Isla, which runs parallel to the nearbySpey, and by the rusty (but usable) railway line to Dufftown withan ancient siding into the grounds.

River water for cooling, spring water for distilling, railsfor Transport, and a sylvan setting. What else could a 19thcentury whisky-maker ask for? But one intriguing question isthis: how long has whisky been made in this perfect location?

Most authorities say that StrathmillDistillery was converted from a flour mill in 1891, but was firstcalled Glenisla-Glenlivet and renamed in 1895 when it was boughtby Gilbey's for £9,500. The flour mill was said to have stoodthere since 1823. But another account suggests that the flourmill itself was a converted distillery building, calledStrathisla, from which the distilling equipment was removed in1837. To confuse matters further, the present-dayStrathisla-Glenlivet is one of Keith's three other workingdistilleries, and was originally called Milltown.

Most authorities say that StrathmillDistillery was converted from a flour mill in 1891, but was firstcalled Glenisla-Glenlivet and renamed in 1895 when it was boughtby Gilbey's for £9,500. The flour mill was said to have stoodthere since 1823. But another account suggests that the flourmill itself was a converted distillery building, calledStrathisla, from which the distilling equipment was removed in1837. To confuse matters further, the present-dayStrathisla-Glenlivet is one of Keith's three other workingdistilleries, and was originally called Milltown.

However, the Strathmill Distillery passed to InternationalDistillers & Vintners in 1962 and is operated by Justerini& Brooks. It produces 52,000 alcohol-litres a week, all ofwhich goes into blends (including J&B Rare).

Indeed, the last known record of Strathmill being on sale as asingle malt is in a Gilbey's advertisement of 1909. It wasbottled at five years old and sold for three shillings (15p toyou) with a penny back on the bottle. The agents for Strathmillwere family grocer's shops in Elgin, Craigellachie, Rothes andLossiemouth.

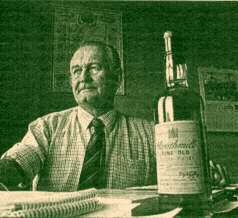

To mark last year's centenary, the two oldest butts in thewarehouse - 25 years old - were bottled for employees andfortunate guests. The distillery manager, Randolph Winchester,had a collector on the phone next day offering him £ 250 for hisbottle, a proposition he politely declined.

The manager has worked at the distillerysince 1959: his first jobs were shovelling coal for the stillsand assisting in the cooperage: so he has seen the stillsconverted to oil-fired steam heating and the coopers depart.

The manager has worked at the distillerysince 1959: his first jobs were shovelling coal for the stillsand assisting in the cooperage: so he has seen the stillsconverted to oil-fired steam heating and the coopers depart.

He has worked in every department at Strathmill. One of thetoughest jobs was cleaning the interior of the wooden washbackswith heather brooms (called besoms). First, he even had to go outand pull up the heather. The stalks were then bound to aneight-foot long pole and he stood inside the washbacks, scouringwith that besom until his shoulders ached.

Of course, much has happened at Strathmill since. The mashingand fermenting vessels are now of stainless steel and it is, infact, one of the neatest and cleanest distilleries you could hopeto see.

Each week, 126 tonnes of lightly-peated malted barley isdelivered by road, often from maltsters in Buckie andPencaitland. This makes 14 mashes, after the malt has gonethrough the German-made Miag six-roller mill and been conveyed tothe mash-tun in proportions of 15 per cent husks, 77 per centmiddles and 8 per cent flour.

There are six 46,500 litre washbacks for fermentation,generated by equal quantities of Maurie and DCl yeast. Enteringthe wash receiver at 32 degrees C, the liquid has its temperaturemore than doubled by recycled heat before going through the firstdistillation.

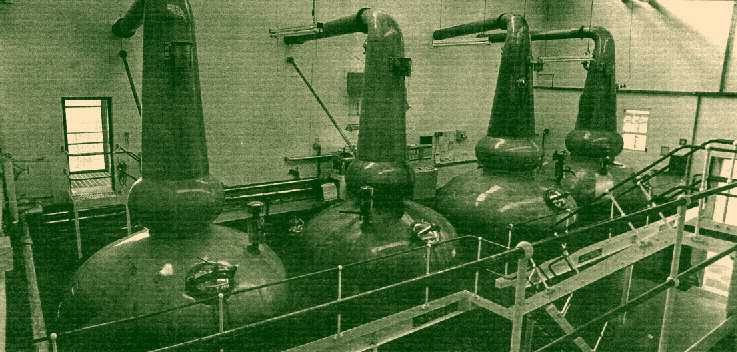

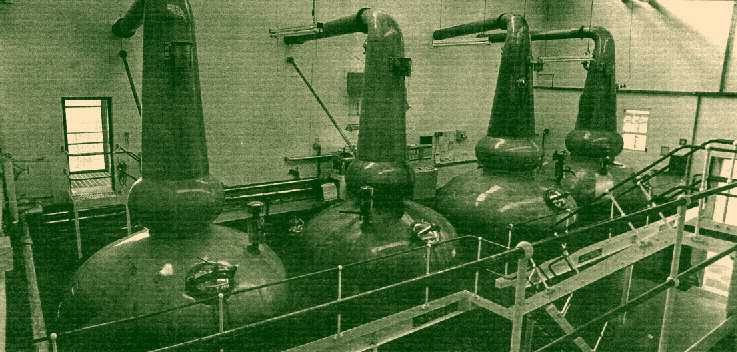

Strathmill has two pairs of stills. The spirit stills areamong the few in the industry fitted with 'purifiers' whichretrieve the heavier fusel oils etc and return them to thedistillation, while the lighter vapours continue to the maincondenser.

With the wash stills taking 45 minutes to come to the boil andthe spirit stills one hour, Strathmill performs its miracle on asix-hour cycle. The middle cut comes through at 71 per centAlcohol by Volume and is reduced with spring water to one of twostandards for filling: 68.5 or 63.5.

The magnificent copper stills were smartened up with a coat oflacquer for the centenary - unfortunately, as it turns out. Thelacquer has not withstood the heat and has taken on a streakypinkish look. Mr Winchester may well return to the old practiceof having the bare copper rubbed over weekly with vegetable oil,giving a superb burnished appearance.

The Strathmill is matured for 10 to 12years, in sherry butts or whisky hogsheads, in the low-roofed,earthen-floored warehouses. A typical delivery to the blenderwill incorporate about 37 per cent from ex-sherry casks.

The Strathmill is matured for 10 to 12years, in sherry butts or whisky hogsheads, in the low-roofed,earthen-floored warehouses. A typical delivery to the blenderwill incorporate about 37 per cent from ex-sherry casks.

At this gem of a distillery, I heard the tale of the 'whiskyfountain'. In the original buildings, whisky straight from thestill was run into open vessels with a mug placed handily 'forany passer-by on friendly terms with the management to helphimself'. I looked everywhere but - damn - it was gone.

If you have comments about thissite, please contact the webmaster. Unless otherwise noted, all information in this siteİ The Scotch Malt Whisky Society, Edinburgh, Scotland, 1997.

It is significant also that ourhundredth whisky is so rare as a bottled single malt that it haseluded even the experts. In his Malt Whisky Companion, MichaelJackson lists it as one of six which appear never to have beenbottled as singles in recent times, even by independent bottlers.So mark well our tasting notes on No 100: you are unlikely to seethem elsewhere.

It is significant also that ourhundredth whisky is so rare as a bottled single malt that it haseluded even the experts. In his Malt Whisky Companion, MichaelJackson lists it as one of six which appear never to have beenbottled as singles in recent times, even by independent bottlers.So mark well our tasting notes on No 100: you are unlikely to seethem elsewhere. Most authorities say that StrathmillDistillery was converted from a flour mill in 1891, but was firstcalled Glenisla-Glenlivet and renamed in 1895 when it was boughtby Gilbey's for £9,500. The flour mill was said to have stoodthere since 1823. But another account suggests that the flourmill itself was a converted distillery building, calledStrathisla, from which the distilling equipment was removed in1837. To confuse matters further, the present-dayStrathisla-Glenlivet is one of Keith's three other workingdistilleries, and was originally called Milltown.

Most authorities say that StrathmillDistillery was converted from a flour mill in 1891, but was firstcalled Glenisla-Glenlivet and renamed in 1895 when it was boughtby Gilbey's for £9,500. The flour mill was said to have stoodthere since 1823. But another account suggests that the flourmill itself was a converted distillery building, calledStrathisla, from which the distilling equipment was removed in1837. To confuse matters further, the present-dayStrathisla-Glenlivet is one of Keith's three other workingdistilleries, and was originally called Milltown. The manager has worked at the distillerysince 1959: his first jobs were shovelling coal for the stillsand assisting in the cooperage: so he has seen the stillsconverted to oil-fired steam heating and the coopers depart.

The manager has worked at the distillerysince 1959: his first jobs were shovelling coal for the stillsand assisting in the cooperage: so he has seen the stillsconverted to oil-fired steam heating and the coopers depart.

The Strathmill is matured for 10 to 12years, in sherry butts or whisky hogsheads, in the low-roofed,earthen-floored warehouses. A typical delivery to the blenderwill incorporate about 37 per cent from ex-sherry casks.

The Strathmill is matured for 10 to 12years, in sherry butts or whisky hogsheads, in the low-roofed,earthen-floored warehouses. A typical delivery to the blenderwill incorporate about 37 per cent from ex-sherry casks.